- Models

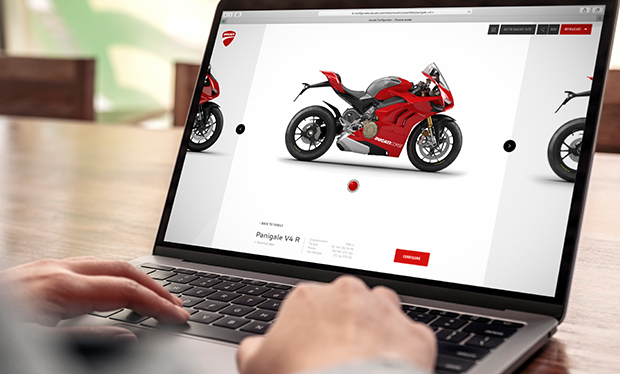

- Configure your bike

- News

- Current Offers

- Racing

- Dealer Locator

- DWP 2025

-

Models

-

DesertX

![]()

-

Diavel

![]()

- Diavel V4

- Diavel For Bentley

Diavel -

Monster

![]()

-

XDiavel

![]()

- new XDiavel V4

XDiavel -

Hypermotard

![]()

- Overview

- 698 Mono RVE

- 698 Mono

- 950 SP

- 950

Hypermotard -

Multistrada

![]()

- Overview

- new V2

- new V2 S

- new V4

- V4 S

- new V4 RS

-

V4 Rally

![]() Multistrada V4 Rally

Multistrada V4 Rally- 170 hp Power

- 89.2 lb-ft Torque

- 525 lb Wet Weight (No Fuel)

Starting From $30,595 i - V4 Pikes Peak

-

V2 S MY24

![]() Multistrada V2 S MY24

Multistrada V2 S MY24- 113 hp Power

- 71 lb-ft Torque

- 485 lb Wet Weight (No Fuel)

Starting from $19,295 i - new V4 Pikes Peak MY25

Multistrada -

Panigale

![]()

-

Streetfighter

![]()

-

V4 Lamborghini

![]() Streetfighter V4 Lamborghini

Streetfighter V4 Lamborghini- 208 hp Power

- 90.4 lb-ft Torque

- 421 lb Wet Weight (No Fuel)

MSRP Starting From $68,000 i - new V4

- new V4 S

- new V2

- new V2 S

- V2 MY24

- V4 MY24

-

V4 S MY24

![]() Streetfighter V4 S MY24

Streetfighter V4 S MY24- 208 hp Power

- 90.4 lb-ft Torque

- 425 lb Wet Weight (No Fuel)

MSRP From $27,795 i - Streetfighter V4 SP2

- new V4 SUPREME®

Streetfighter -

V4 Lamborghini

-

SuperSport

![]()

-

![]()

-

Desmo450 MX

![]()

-

new

Desmo450 MX

![]() Desmo450 MX

Desmo450 MX- 63.5 hp @ 9,400 rpm Power

- 39.5 lb-ft @ 7,500 rpm Torque

- 231 lb Wet Weight (No Fuel)

$11,495 i

Desmo450 MX -

new

Desmo450 MX

-

E-BIKE

![]()

-

Limited Series

![]()

- new Panigale V4 Lamborghini

-

new

V4 Tricolore Italia

![]() Panigale V4 Tricolore ItaliaAn unforgettable day. To be re-lived forever.

Panigale V4 Tricolore ItaliaAn unforgettable day. To be re-lived forever.- 209 hp Power

- 89.5 lb-ft @ 11,250 rpm Torque

- 414 lb Wet Weight (No Fuel)

$85,000 i - new V4 Tricolore

- Ducati Speciale

- Ducati Unica

Limited Series

-

- Equipment

- Current Offers

- DWP 2026

Bikes

DesertX

Diavel

Hypermotard

Streetfighter

Multistrada

Panigale

Off-Road

Supersport

E-BIKES

Contact a Dealer

Get in touch with your nearest dealer for all your Ducati needs.

Brochures

Discover all the details of your favourite Ducati and download the brochure!

Contact a Dealer

Get in touch with your nearest dealer for all your Ducati needs.

Brochures

Discover all the details of your favourite Ducati and download the brochure!

Equipment

Accessories

Configurator

Choose the perfect Ducati for you and have fun configuring it according to your riding style.

Accessories

Discover the accessories available for your Ducati

Apparel

View the full range of the Ducati Apparel collection

Configurator

Choose the perfect Ducati for you and have fun configuring it according to your riding style.

Accessories

Discover the accessories available for your Ducati

Racing

MotoGP

Superbike

OFF-ROAD

MotoE

Ducati World

Events

Ducati Academy

Press Reviews

Travel With Ducati

Ducati Stories

News

Ducati Redline Magazine

A selection of the most exclusive content from the Ducati Redline Magazine. Download read the stories here!

News

Read the latest news stories to find out what is happening in the world of Ducati

DOC

Imagine enjoying new experiences, exploring breath-taking landscapes, participating in exclusive events. Join the Ducati family! Become a D.O.C. member!

Ducati Redline Magazine

A selection of the most exclusive content from the Ducati Redline Magazine. Download read the stories here!

News

Read the latest news stories to find out what is happening in the world of Ducati

Service and Maintenance

Maintenance

Connectivity

Dealer Network

Multistrada V4 Video Tutorials

Learn how to operate the features of the Multistrada V4 through these video tutorials

Dealer Locator

Find you nearest Ducati dealership by using the Ducati Dealer Locator

Ducati Financial Services

From traditional financing to our exclusive Ducati Premier Financing, Ducati Financial Services offers a wide range of options and flexible terms.

Multistrada V4 Video Tutorials

Learn how to operate the features of the Multistrada V4 through these video tutorials

Dealer Locator

Find you nearest Ducati dealership by using the Ducati Dealer Locator

Corporate

Design

Corporate Social Responsibility

Partners

Fondazione Ducati

Borgo Panigale

Customer Services

To make it easier for you to find your way around, we have created a list of the most frequently asked questions, divided into subject areas, along with their answers.

Work with us

Find the latest job opportunities available for Ducati North America

Customer Services

To make it easier for you to find your way around, we have created a list of the most frequently asked questions, divided into subject areas, along with their answers.

Work with us

Find the latest job opportunities available for Ducati North America

Models

DesertX

New

Diavel

New

Monster

New

XDiavel

New

Hypermotard

Multistrada

New

Panigale

New

Streetfighter

New

SuperSport

SCRAMBLER

Desmo450 MX

New

E-BIKE

Limited Series

Racing

- MotoGP

- Superbike

- Off Road

- MotoE

Ducati World

- Events

- Ducati Academy

- Ducati Press Reviews

- Ducati Travel Adventures

- Ducati Stories

- News

DOC

Imagine enjoying new experiences, exploring breath-taking landscapes, participating in exclusive events. Join the Ducati family! Become a D.O.C. member!

DOC

Ducati Redline Magazine

A selection of the most exclusive content from the Ducati Redline Magazine. Download read the stories here!

Ducati Redline Magazine

Equipment

- Accessories

- Apparel

Configurator

Choose the perfect Ducati for you and have fun configuring it according to your riding style.

Configurator

Service and Maintenance

- Services

- Maintenance

- Connectivity

- Dealer Network

Ducati Financial Services

From traditional financing to our exclusive Ducati Premier Financing, Ducati Financial Services offers a wide range of options and flexible terms.

Ducati Financial Services

Multistrada V4 Video Tutorials

Learn how to operate the features of the Multistrada V4 through these video tutorials

Multistrada V4 Video Tutorials

Ducati Club

Corporate

- Who We Are

- Product Innovation

- Corporate

- Partners

- Fondazione Ducati

- Borgo Panigale

Customer Services

To make it easier for you to find your way around, we have created a list of the most frequently asked questions, divided into subject areas, along with their answers.

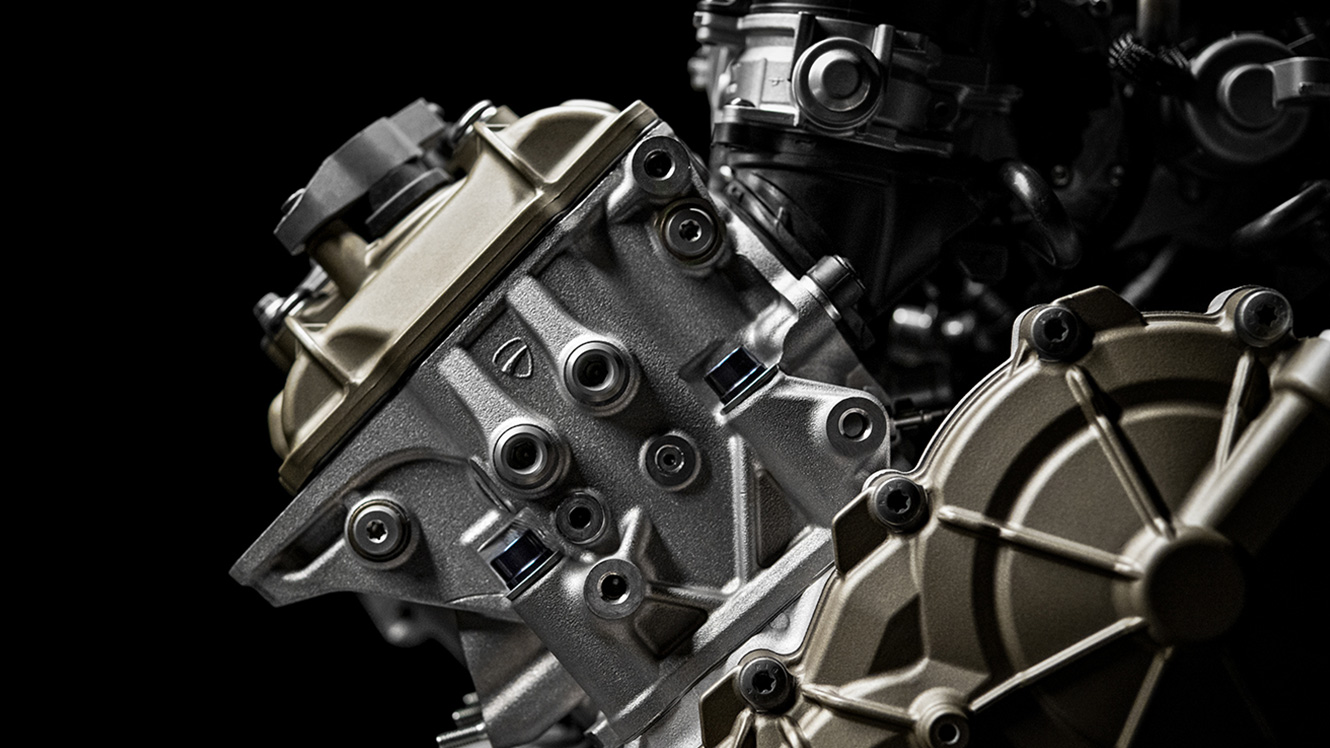

Customer ServicesLightweight Power

Interview with Enrico Poluzzi, Ducati Engine Design Manager.

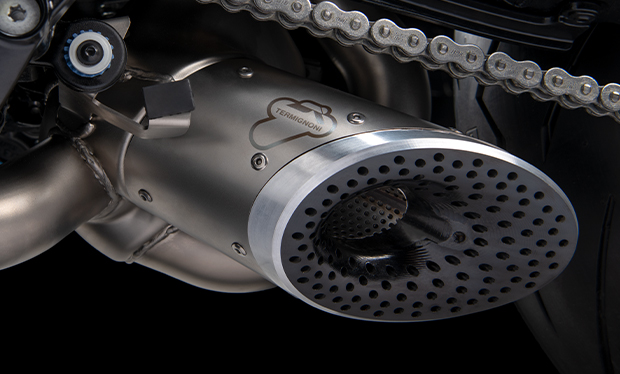

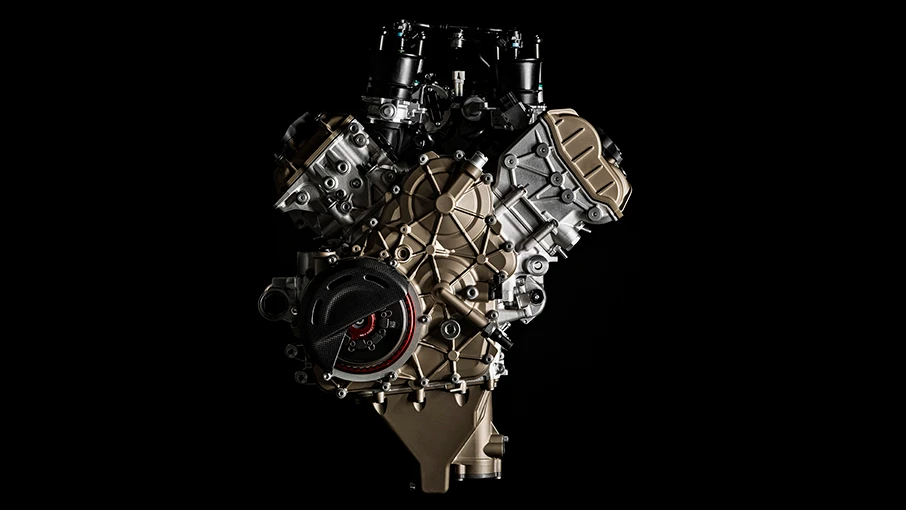

The engine design is undoubtedly one of the most distinctive features of Ducati. A field in which the desmodromic timing system has become a signature feature. Developing the engine for project Superleggera V4 means making the most sophisticated Ducati engine ever made. Piece by piece, working on every single component to make it as light as possible. Finding space for innovation in every detail.

“Starting work on the Superleggera V4 was really exciting: we were free to think about unconventional solutions and to let our creativity run wild. It’s a much bigger playing field; my team was blessed with the opportunity of designing without any pressure in terms of costs or experimental levels and to have access to materials, processes, technologies that we normally use only in competitions.

It’s also an extremely engaging moment for everyone, because each working group knows which components have technical margins and technological alternatives and therefore put its specific know-how in the line. It’s a project where the mandate is to do impossible things”.

Enthusiasm is followed by the expertise of technical engineering development. Much like every other aspect of project Superleggera V4, engine development left no room for chance. A complete analysis of each micro engine component is carried out to understand the evolutionary opportunities, test new materials and new geometries. The idea is to open to futuristic research in order to make something unprecedented.

“When the project started we went over the engine’s list of components and 600 part numbers. We analyzed all the components and then decided which to focus on. For some a search for experimental solutions began, while for others we knew that there was room for improvement because we already knew the current limits and margins for further development.

Priority is given to components made of higher density materials to evaluate replacement with lighter materials. We changed all the bolts for the bases and heads from steel to titanium. The same was also done for smaller bolts, like the ones on the camshaft supports. Small components yet very numerous. ”

The choice of materials is the first step, but a meticulous work on the geometries is also required, which develops in two different directions: the first to check that new materials do not present application difficulties, the second to improve and lighten the existing components.

“Many components were optimised by thinning the thicknesses and introducing lightening originally not present. With the same approach, starter gears and camshafts have been machined with additional lightening holes on the lobes and longitudinally by decreasing the cross-section over the entire length of the shaft.

42% of the components were redesigned to gain, in some cases, only a few dozen grams. When added to one another, though, the gain was quite sizeable and amounted to an overall reduction of 6.17 lb in comparison with our Panigale V4 S engine.

A component for which we managed to achieve a remarkable weight reduction is the oil pump assembly; we drastically simplified the assembly design and reduced the number of recovery pumps from 3 to 2. Thanks to the completely new design of inner pump ducts we managed to keep the assembly function unchanged, that is, the new pumps drain the oil from the same areas and with the same efficacy as the old system.”

“Starting work on the Superleggera V4 was really exciting: we were free to think about unconventional solutions and to let our creativity run wild".

The development work of this engine adds unique features also to the driving feel. Both for the lightening in the changes of direction, but above all for the increase of the reactivity that is generated by intervening on the inertia of the flywheel components. Ducati engineering skills are 100% exploited in every step, to create an engine that has its own specific character.

“Compared to the basic V4 all the flywheel parts were lightened, mainly using titanium con-rods (and therefore also lightening the crankshaft counterweights). The elements that make the largest contribution to the engine rotating masses inertia were all lightened: this means that the engine can increase and decrease RPMs more quickly. So the engine is designed to react instantly to the rider’s demands.

It was hard and painstaking work, in that the starting components in the standard engine already feature high optimisation levels. Therefore we had to focus on details, add holes, decrease thickness values to reduce weight but – needless to say – not to the detriment of reliability: Superleggera V4 engine components are approved by applying the same standards used for the components of every other engine, without any preferential treatment.”

Each engine component has been brought to the limit. The complexity of the processes is much higher. As a consequence, all checks and simulations must show to be up to this, to add a craft approach while ensuring industrial reliability. Enrico’s team submits the project to FEM hours and structural simulation. For the Superleggera V4 engine, Ducati performs an extremization process similar to what is done by Ducati Corse for racing engines, but with safety coefficients adequate to a type-approval product.

“It’s a racing engine, but it has to have a lifetime guarantee. And this requires some extra attention. For example, titanium is a noble material but it generates more friction on sliding surfaces. This must be considered in the screws, since a certain axial load must be guaranteed to the tightening. That’s why we’ve used a special coating to eliminate this issue entirely”.

Being tasked with accomplishing excellence allows Ducati to grow individually and as part of a group; indeed, the discarded ideas push the whole team to looking for new, experimental technology innovations. It

is a search towards new performance boundaries that lays the foundations for the future, generating a truly exclusive engine-hearted-creature.

“Taking part in the development of the Superleggera V4 engine is truly a unique experience. It’s a job that fills the whole team with pride, but also generates enthusiasm and energy thanks to the creative freedom that was granted. It has become an experience of research and development that has a global impact on the team’s knowledge. We’re encouraged for new solutions even out of the box. This allows us to be daring and see the project as an expression of our skills and ourselves. It’s a great sense of accomplishment”.

Continue to explore

Superleggera V4 is a Ducati project in every way, in which we have tried to respond to the unknowns with engineering, overcoming the limits of feasibility and transforming lightness into the total emotion of speed.

Discover the interviews with the Ducati engineers who designed and built the bike of your dreams!

United States

United States

DesertX

DesertX  Diavel

Diavel Monster

Monster XDiavel

XDiavel Hypermotard

Hypermotard

Multistrada

Multistrada Panigale

Panigale Streetfighter

Streetfighter SuperSport

SuperSport

Desmo450 MX

Desmo450 MX E-BIKE

E-BIKE

Limited Series

Limited Series