- Models

- Configure your bike

- News

- Current Offers

- Racing

- Dealer Locator

- DWP 2025

-

Models

-

DesertX

![]()

-

Diavel

![]()

- Diavel V4

- Diavel For Bentley

Diavel -

Monster

![]()

-

XDiavel

![]()

- new XDiavel V4

XDiavel -

Hypermotard

![]()

- Overview

- 698 Mono RVE

- 698 Mono

- 950 SP

- 950

Hypermotard -

Multistrada

![]()

- Overview

- new V2

- new V2 S

- new V4

- V4 S

- new V4 RS

-

V4 Rally

![]() Multistrada V4 Rally

Multistrada V4 Rally- 170 hp Power

- 89.2 lb-ft Torque

- 525 lb Wet Weight (No Fuel)

Starting From $30,595 i - V4 Pikes Peak

-

V2 S MY24

![]() Multistrada V2 S MY24

Multistrada V2 S MY24- 113 hp Power

- 71 lb-ft Torque

- 485 lb Wet Weight (No Fuel)

Starting from $19,295 i - new V4 Pikes Peak MY25

Multistrada -

Panigale

![]()

-

Streetfighter

![]()

-

V4 Lamborghini

![]() Streetfighter V4 Lamborghini

Streetfighter V4 Lamborghini- 208 hp Power

- 90.4 lb-ft Torque

- 421 lb Wet Weight (No Fuel)

MSRP Starting From $68,000 i - new V4

- new V4 S

- new V2

- new V2 S

- V2 MY24

- V4 MY24

-

V4 S MY24

![]() Streetfighter V4 S MY24

Streetfighter V4 S MY24- 208 hp Power

- 90.4 lb-ft Torque

- 425 lb Wet Weight (No Fuel)

MSRP From $27,795 i - Streetfighter V4 SP2

- new V4 SUPREME®

Streetfighter -

V4 Lamborghini

-

SuperSport

![]()

-

![]()

-

Desmo450 MX

![]()

-

new

Desmo450 MX

![]() Desmo450 MX

Desmo450 MX- 63.5 hp @ 9,400 rpm Power

- 39.5 lb-ft @ 7,500 rpm Torque

- 231 lb Wet Weight (No Fuel)

$11,495 i

Desmo450 MX -

new

Desmo450 MX

-

E-BIKE

![]()

-

Limited Series

![]()

- new Panigale V4 Lamborghini

-

new

V4 Tricolore Italia

![]() Panigale V4 Tricolore ItaliaAn unforgettable day. To be re-lived forever.

Panigale V4 Tricolore ItaliaAn unforgettable day. To be re-lived forever.- 209 hp Power

- 89.5 lb-ft @ 11,250 rpm Torque

- 414 lb Wet Weight (No Fuel)

$85,000 i - new V4 Tricolore

- Ducati Speciale

- Ducati Unica

Limited Series

-

- Equipment

- Current Offers

- DWP 2026

Bikes

DesertX

Diavel

Hypermotard

Streetfighter

Multistrada

Panigale

Off-Road

Supersport

E-BIKES

Equipment

Accessories

Racing

MotoGP

Superbike

OFF-ROAD

MotoE

Ducati World

Events

Ducati Academy

Press Reviews

Travel With Ducati

Ducati Stories

News

News

Read the latest news stories to find out what is happening in the world of Ducati

DOC

Imagine enjoying new experiences, exploring breath-taking landscapes, participating in exclusive events. Join the Ducati family! Become a D.O.C. member!

Ducati Redline Magazine

A selection of the most exclusive content from the Ducati Redline Magazine. Download read the stories here!

Service and Maintenance

Maintenance

Connectivity

Dealer Network

Dealer Locator

Find you nearest Ducati dealership by using the Ducati Dealer Locator

Ducati Financial Services

From traditional financing to our exclusive Ducati Premier Financing, Ducati Financial Services offers a wide range of options and flexible terms.

Multistrada V4 Video Tutorials

Learn how to operate the features of the Multistrada V4 through these video tutorials

Corporate

Design

Corporate Social Responsibility

Partners

Fondazione Ducati

Borgo Panigale

Models

DesertX

New

Diavel

New

Monster

New

XDiavel

New

Hypermotard

Multistrada

New

Panigale

New

Streetfighter

New

SuperSport

SCRAMBLER

Desmo450 MX

New

E-BIKE

Limited Series

Racing

- MotoGP

- Superbike

- Off Road

- MotoE

Ducati World

- Events

- Ducati Academy

- Ducati Press Reviews

- Ducati Travel Adventures

- Ducati Stories

- News

DOC

Imagine enjoying new experiences, exploring breath-taking landscapes, participating in exclusive events. Join the Ducati family! Become a D.O.C. member!

DOC

Ducati Redline Magazine

A selection of the most exclusive content from the Ducati Redline Magazine. Download read the stories here!

Ducati Redline Magazine

Equipment

- Accessories

- Apparel

Configurator

Choose the perfect Ducati for you and have fun configuring it according to your riding style.

Configurator

Service and Maintenance

- Services

- Maintenance

- Connectivity

- Dealer Network

Ducati Financial Services

From traditional financing to our exclusive Ducati Premier Financing, Ducati Financial Services offers a wide range of options and flexible terms.

Ducati Financial Services

Multistrada V4 Video Tutorials

Learn how to operate the features of the Multistrada V4 through these video tutorials

Multistrada V4 Video Tutorials

Ducati Club

Corporate

- Who We Are

- Product Innovation

- Corporate

- Partners

- Fondazione Ducati

- Borgo Panigale

Customer Services

To make it easier for you to find your way around, we have created a list of the most frequently asked questions, divided into subject areas, along with their answers.

Customer ServicesDream Molecules

Interview with Leonardo Bagnoli, Ducati Head of Vehicle Simulation

Materials research has always been an obsession for Ducati. If we think of our founding values, style, sophistication and performance, we find them all in this innovative research activity. T

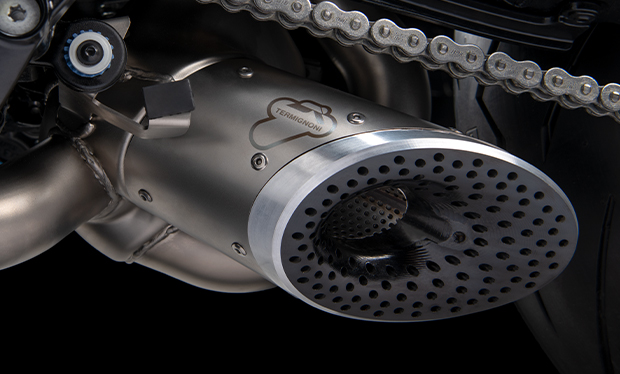

The precious materials we work with, especially titanium, magnesium and carbon fiber, are the backbone of the vehicle’s dynamics and at the same time give our racing bikes that unmistakable Ducati look.

“Materials research is extremely expensive and difficult. Because it’s necessary to test different areas, considering the type of material and the best shapes to make it perform at its best. A few millimetres can be the difference between a huge success and a failure”.

The Superleggera V4 takes this extreme approach, which we inherit from our daily activity in the world of GP and SBK competitions, to a completely new, even more complex level. Although extreme in fact, the world of competitions has a limited duration in time. Ducati research is best expressed in exasperating the characteristics of the materials, calculating in advance the number of cycles and the type of mechanical stress to which they will be subjected.

“When doing research there’s an element of challenge. Of solving an enigma. Complexity needs to be dealt with head on and resolved in new ways.

For the Superleggera V4 the challenge was completely different from a racing prototype: we have to achieve extreme performance while safeguarding reliability and meeting type-approval requirements. It’s a question of making the most of the characteristics of materials and components without being able to predict the real stress they will be subjected to, creating components with experimental technologies to apply them to a motorcycle that’s not just for a single specific rider, but must be ready for standard type-approval.

The component we design doesn’t just have to get through 10 races. It has to last forever. And so the work of calculation and simulation is twice as much as for any other bike we produce”.

“Materials research is extremely expensive and difficult. Because it’s necessary to test different areas, considering the type of material and the best shapes to make it perform at its best. A few millimetres can be the difference between a huge success and a failure”.

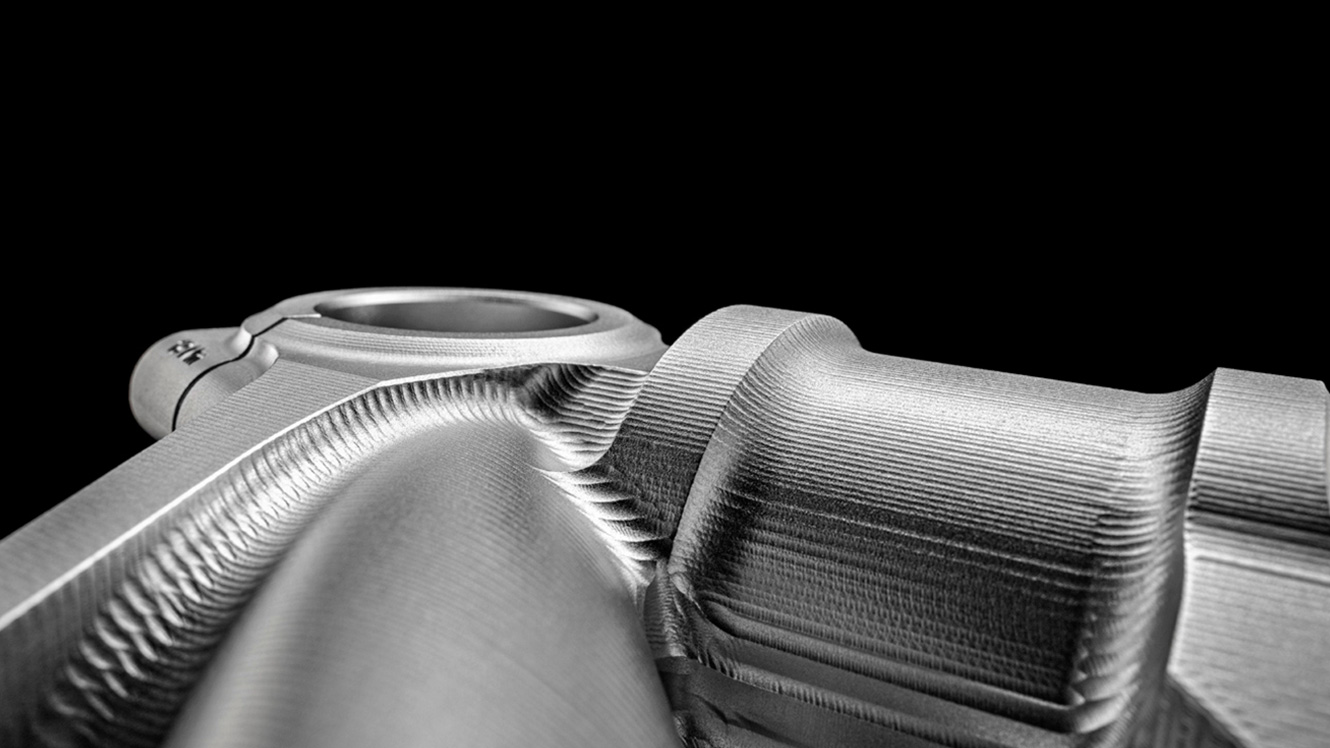

Each component is studied with techniques and technologies in which art, craftsmanship and industry meet. We follow a testing process usually applied in aeronautics, each component passes thermographic, ultrasound and even tomographic checks. We do a CT scan of each piece to verify the internal structure as well as the external one.

The Leonardo team divides the tasks and each engineer takes care of bringing a single component of the Superleggera V4 project to perfection, carrying out the necessary virtual tests to push each material to the maximum. An important example is the new carbon rear swingarm, where for the first time it has been possible to apply unidirectional carbon, a very difficult material to tame. Unidirectional carbon is highly performing due to the relationship between weight and stiffness, but highly anisotropic and therefore complex to stabilize.

“The complexity of the surfaces greatly influences the possibility of using a futuristic material like single-sided carbon, so we had to completely redesign the geometry of the rear swinging arm to improve it, in a constant dialogue with the design center to remain consistent with Ducati design. Morphological optimization was one of the activities that occupied us the most in testing and virtual resistance simulations.

The result is a specific stiffness ratio never achieved before. A bike lightened in all the most peripheral loads and therefore incredibly more agile and manageable. But also more stable thanks to the new geometries”.

The balance achieved is really of the highest level, even in the combination of different types of carbon in the frame, in which chemical compatibility was also sought, between resins and materials. Experimental research is not an end in itself, it is an aspirational statement for the whole company. And it is the activity with which Ducati constantly strives to raise the bar for itself and for the world of motorcycling.

“For a structural engineer, defining lightweight structures, working on the most exclusive motorcycle on the planet is a way of seeing knowledge applied in an actual project that is able to put it to use. Take performance to the extreme. Find professional satisfaction by using all the skills learned over the years in a unique project”.

Continue to explore

Superleggera V4 is a Ducati project in every way, in which we have tried to respond to the unknowns with engineering, overcoming the limits of feasibility and transforming lightness into the total emotion of speed.

Discover the interviews with the Ducati engineers who designed and built the bike of your dreams!

New Superleggera V4

335.5 lb dry weight for 234 HP (in race configuration) for this incredible product. These numbers are achieved thanks to the full carbon fiber frame and a vast use of titanium and magnesium components.

Discover it United States

United States

DesertX

DesertX  Diavel

Diavel Monster

Monster XDiavel

XDiavel Hypermotard

Hypermotard

Multistrada

Multistrada Panigale

Panigale Streetfighter

Streetfighter SuperSport

SuperSport

Desmo450 MX

Desmo450 MX E-BIKE

E-BIKE

Limited Series

Limited Series